Chemical Datasheet

DIETHANOLAMINE |

|

Chemical Identifiers

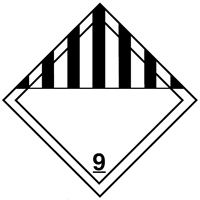

The

Chemical Identifier fields

include common identification numbers, the

NFPA diamond

U.S. Department of Transportation hazard labels, and a general

description of the chemical. The information in CAMEO Chemicals comes

from a variety of

data sources.

| CAS Number | UN/NA Number | DOT Hazard Label | USCG CHRIS Code |

|---|---|---|---|

|

|

||

| NIOSH Pocket Guide | International Chem Safety Card | ||

Diethanolamine

|

|||

NFPA 704

| Diamond | Hazard | Value | Description | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

3 | Can cause serious or permanent injury. | |||||||||

|

|

1 | Must be preheated before ignition can occur. | ||||||||||

|

|

0 | Normally stable, even under fire conditions. | ||||||||||

|

|

(NFPA, 2010)

General Description

Oily colorless liquid or solid white crystals. Slight rotten fish or ammonia odor. Denser than water. (USCG, 1999)

Hazards

The

Hazard fields

include

special hazard alerts

air and water

reactions, fire hazards, health hazards, a reactivity profile, and

details about

reactive groups assignments

and

potentially incompatible absorbents.

The information in CAMEO Chemicals comes from a variety of

data sources.

Reactivity Alerts

none

Air & Water Reactions

Water soluble.

Fire Hazard

Special Hazards of Combustion Products: Irritating vapors are generated when heated. (USCG, 1999)

Health Hazard

Irritation of eyes and skin. Breathing vapors may cause coughing, a smothering sensation, nausea, headache. (USCG, 1999)

Reactivity Profile

DIETHANOLAMINE is an aminoalcohol. Amines are chemical bases. They neutralize acids to form salts plus water. These acid-base reactions are exothermic. The amount of heat that is evolved per mole of amine in a neutralization is largely independent of the strength of the amine as a base. Amines may be incompatible with isocyanates, halogenated organics, peroxides, phenols (acidic), epoxides, anhydrides, and acid halides. Flammable gaseous hydrogen is generated by amines in combination with strong reducing agents, such as hydrides. This compound is hygroscopic. It may be sensitive to exposure to air and light. This compound can react with oxidizing materials, acids, CO2, copper alloys, aluminum, zinc, galvanized iron and copper. (NTP, 1992)

Belongs to the Following Reactive Group(s)

Potentially Incompatible Absorbents

Use caution: Liquids with this reactive group classification have been known to react with the absorbents listed below. More info about absorbents, including situations to watch out for...

- Cellulose-Based Absorbents

- Mineral-Based & Clay-Based Absorbents

Response Recommendations

The

Response Recommendation fields

include isolation and evacuation distances, as well as recommendations for

firefighting, non-fire response, protective clothing, and first aid. The

information in CAMEO Chemicals comes from a variety of

data sources.

Isolation and Evacuation

Excerpt from ERG Guide 171 [Substances (Low to Moderate Hazard)]:

IMMEDIATE PRECAUTIONARY MEASURE: Isolate spill or leak area in all directions for at least 50 meters (150 feet) for liquids and at least 25 meters (75 feet) for solids.

SPILL: Increase the immediate precautionary measure distance, in the downwind direction, as necessary.

FIRE: If tank, rail tank car or highway tank is involved in a fire, ISOLATE for 800 meters (1/2 mile) in all directions; also, consider initial evacuation for 800 meters (1/2 mile) in all directions. (ERG, 2024)

IMMEDIATE PRECAUTIONARY MEASURE: Isolate spill or leak area in all directions for at least 50 meters (150 feet) for liquids and at least 25 meters (75 feet) for solids.

SPILL: Increase the immediate precautionary measure distance, in the downwind direction, as necessary.

FIRE: If tank, rail tank car or highway tank is involved in a fire, ISOLATE for 800 meters (1/2 mile) in all directions; also, consider initial evacuation for 800 meters (1/2 mile) in all directions. (ERG, 2024)

Firefighting

Excerpt from ERG Guide 171 [Substances (Low to Moderate Hazard)]:

CAUTION: Fire involving Safety devices (UN3268) and Fire suppressant dispersing devices (UN3559) may have a delayed activation and a risk of hazardous projectiles. Extinguish the fire at a safe distance.

SMALL FIRE: Dry chemical, CO2, water spray or regular foam.

LARGE FIRE: Water spray, fog or regular foam. Do not scatter spilled material with high-pressure water streams. If it can be done safely, move undamaged containers away from the area around the fire. Dike runoff from fire control for later disposal.

FIRE INVOLVING TANKS: Cool containers with flooding quantities of water until well after fire is out. Withdraw immediately in case of rising sound from venting safety devices or discoloration of tank. ALWAYS stay away from tanks in direct contact with flames. (ERG, 2024)

CAUTION: Fire involving Safety devices (UN3268) and Fire suppressant dispersing devices (UN3559) may have a delayed activation and a risk of hazardous projectiles. Extinguish the fire at a safe distance.

SMALL FIRE: Dry chemical, CO2, water spray or regular foam.

LARGE FIRE: Water spray, fog or regular foam. Do not scatter spilled material with high-pressure water streams. If it can be done safely, move undamaged containers away from the area around the fire. Dike runoff from fire control for later disposal.

FIRE INVOLVING TANKS: Cool containers with flooding quantities of water until well after fire is out. Withdraw immediately in case of rising sound from venting safety devices or discoloration of tank. ALWAYS stay away from tanks in direct contact with flames. (ERG, 2024)

Non-Fire Response

Excerpt from ERG Guide 171 [Substances (Low to Moderate Hazard)]:

Do not touch or walk through spilled material. Stop leak if you can do it without risk. Prevent dust cloud. For Asbestos, avoid inhalation of dust. Cover spill with plastic sheet or tarp to minimize spreading. Do not clean up or dispose of, except under supervision of a specialist.

SMALL DRY SPILL: With clean shovel, place material into clean, dry container and cover loosely; move containers from spill area.

SMALL SPILL: Pick up with sand or other non-combustible absorbent material and place into containers for later disposal.

LARGE SPILL: Dike far ahead of liquid spill for later disposal. Cover powder spill with plastic sheet or tarp to minimize spreading. Prevent entry into waterways, sewers, basements or confined areas. (ERG, 2024)

Do not touch or walk through spilled material. Stop leak if you can do it without risk. Prevent dust cloud. For Asbestos, avoid inhalation of dust. Cover spill with plastic sheet or tarp to minimize spreading. Do not clean up or dispose of, except under supervision of a specialist.

SMALL DRY SPILL: With clean shovel, place material into clean, dry container and cover loosely; move containers from spill area.

SMALL SPILL: Pick up with sand or other non-combustible absorbent material and place into containers for later disposal.

LARGE SPILL: Dike far ahead of liquid spill for later disposal. Cover powder spill with plastic sheet or tarp to minimize spreading. Prevent entry into waterways, sewers, basements or confined areas. (ERG, 2024)

Protective Clothing

Excerpt from NIOSH Pocket Guide for Diethanolamine :

:

Skin: PREVENT SKIN CONTACT - Wear appropriate personal protective clothing to prevent skin contact.

Eyes: PREVENT EYE CONTACT - Wear appropriate eye protection to prevent eye contact.

Wash skin: WHEN CONTAMINATED - The worker should immediately wash the skin when it becomes contaminated.

Remove: WHEN WET OR CONTAMINATED - Work clothing that becomes wet or significantly contaminated should be removed and replaced.

Change: DAILY - Workers whose clothing may have become contaminated should change into uncontaminated clothing before leaving the work premises.

Provide:

• EYEWASH - Eyewash fountains should be provided in areas where there is any possibility that workers could be exposed to the substances; this is irrespective of the recommendation involving the wearing of eye protection.

• QUICK DRENCH - Facilities for quickly drenching the body should be provided within the immediate work area for emergency use where there is a possibility of exposure. [Note: It is intended that these facilities provide a sufficient quantity or flow of water to quickly remove the substance from any body areas likely to be exposed. The actual determination of what constitutes an adequate quick drench facility depends on the specific circumstances. In certain instances, a deluge shower should be readily available, whereas in others, the availability of water from a sink or hose could be considered adequate.] (NIOSH, 2024)

:

:Skin: PREVENT SKIN CONTACT - Wear appropriate personal protective clothing to prevent skin contact.

Eyes: PREVENT EYE CONTACT - Wear appropriate eye protection to prevent eye contact.

Wash skin: WHEN CONTAMINATED - The worker should immediately wash the skin when it becomes contaminated.

Remove: WHEN WET OR CONTAMINATED - Work clothing that becomes wet or significantly contaminated should be removed and replaced.

Change: DAILY - Workers whose clothing may have become contaminated should change into uncontaminated clothing before leaving the work premises.

Provide:

• EYEWASH - Eyewash fountains should be provided in areas where there is any possibility that workers could be exposed to the substances; this is irrespective of the recommendation involving the wearing of eye protection.

• QUICK DRENCH - Facilities for quickly drenching the body should be provided within the immediate work area for emergency use where there is a possibility of exposure. [Note: It is intended that these facilities provide a sufficient quantity or flow of water to quickly remove the substance from any body areas likely to be exposed. The actual determination of what constitutes an adequate quick drench facility depends on the specific circumstances. In certain instances, a deluge shower should be readily available, whereas in others, the availability of water from a sink or hose could be considered adequate.] (NIOSH, 2024)

DuPont Tychem® Suit Fabrics

Tychem® Fabric Legend

| QS = Tychem 2000 SFR |

| QC = Tychem 2000 |

| SL = Tychem 4000 |

| C3 = Tychem 5000 |

| TF = Tychem 6000 |

| TP = Tychem 6000 FR |

| RC = Tychem RESPONDER® CSM |

| TK = Tychem 10000 |

| RF = Tychem 10000 FR |

Testing Details

The fabric permeation data was generated for DuPont by a third party

laboratory. Permeation data for industrial chemicals is obtained per

ASTM F739. Normalized breakthrough times (the time at which the

permeation rate exceeds 0.1 μg/cm2/min) are reported in minutes. All

chemicals have been tested between approximately 20°C and 27°C unless

otherwise stated. All chemicals have been tested at a concentration of

greater than 95% unless otherwise stated.

Chemical warfare agents (Lewisite, Sarin, Soman, Sulfur Mustard, Tabun

and VX Nerve Agent) have been tested at 22°C and 50% relative humidity

per military standard MIL-STD-282. "Breakthrough time" for chemical

warfare agents is defined as the time when the cumulative mass which

permeated through the fabric exceeds the limit in MIL-STD-282 [either

1.25 or 4.0 μg/cm2].

A Caution from DuPont

This information is based upon technical data that DuPont believes to

be reliable on the date issued. It is subject to revision as additional

knowledge and experience are gained. The information reflects

laboratory performance of fabrics, not complete garments, under

controlled conditions. It is intended for informational use by persons

having technical skill for evaluation under their specific end-use

conditions, at their own discretion and risk. It is the user's

responsibility to determine the level of toxicity and the proper

personal protective equipment needed. Anyone intending to use this

information should first verify that the garment selected is suitable

for the intended use. In many cases, seams and closures have shorter

breakthrough times and higher permeation rates than the fabric. If

fabric becomes torn,abraded or punctured, or if seams or closures fail,

or if attached gloves, visors, etc. are damaged, end user should

discontinue use of garment to avoid potential exposure to chemical.

Since conditions of use are outside our control, DuPont makes no

warranties, express or implied, including, without limitation, no

warranties of merchantability or fitness for a particular use and

assume no liability in connection with any use of this information.

This information is not intended as a license to operate under or a

recommendation to infringe any patent, trademark or technical

information of DuPont or others covering any material or its use.

| Chemical | CAS Number | State | QS | QC | SL | C3 | TF | TP | RC | TK | RF |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Diethanolamine | 111-42-2 | Liquid | >480 | >480 |

> indicates greater than.

Special Warning from DuPont: Tychem® and Tyvek® fabrics should not be used around heat, flames, sparks or in potentially flammable or explosive environments. Only...

...Tychem® ThermoPro, Tychem® Reflector® and Tychem® TK styles 600T/601T

(with aluminized outer suit) garments are designed and tested to help

reduce burn injury during escape from a flash fire. Users of Tychem®

ThermoPro, Tychem® Reflector® and Tychem® TK styles 600T/601T (with

aluminized outer suit) garments should not knowingly enter an explosive

environment. Tychem® garments with attached socks must be worn inside

protective outer footwear and are not suitable as outer footwear. These

attached socks do not have adequate durability or slip resistance to be

worn as the outer foot covering.

(DuPont, 2024)

First Aid

EYES: First check the victim for contact lenses and remove if present. Flush victim's eyes with water or normal saline solution for 20 to 30 minutes while simultaneously calling a hospital or poison control center. Do not put any ointments, oils, or medication in the victim's eyes without specific instructions from a physician. IMMEDIATELY transport the victim after flushing eyes to a hospital even if no symptoms (such as redness or irritation) develop.

SKIN: IMMEDIATELY flood affected skin with water while removing and isolating all contaminated clothing. Gently wash all affected skin areas thoroughly with soap and water. IMMEDIATELY call a hospital or poison control center even if no symptoms (such as redness or irritation) develop. IMMEDIATELY transport the victim to a hospital for treatment after washing the affected areas.

INHALATION: IMMEDIATELY leave the contaminated area; take deep breaths of fresh air. If symptoms (such as wheezing, coughing, shortness of breath, or burning in the mouth, throat, or chest) develop, call a physician and be prepared to transport the victim to a hospital. Provide proper respiratory protection to rescuers entering an unknown atmosphere. Whenever possible, Self-Contained Breathing Apparatus (SCBA) should be used; if not available, use a level of protection greater than or equal to that advised under Protective Clothing.

INGESTION: DO NOT INDUCE VOMITING. Corrosive chemicals will destroy the membranes of the mouth, throat, and esophagus and, in addition, have a high risk of being aspirated into the victim's lungs during vomiting which increases the medical problems. If the victim is conscious and not convulsing, give 1 or 2 glasses of water to dilute the chemical and IMMEDIATELY call a hospital or poison control center. IMMEDIATELY transport the victim to a hospital. If the victim is convulsing or unconscious, do not give anything by mouth, ensure that the victim's airway is open and lay the victim on his/her side with the head lower than the body. DO NOT INDUCE VOMITING. Transport the victim IMMEDIATELY to a hospital. (NTP, 1992)

SKIN: IMMEDIATELY flood affected skin with water while removing and isolating all contaminated clothing. Gently wash all affected skin areas thoroughly with soap and water. IMMEDIATELY call a hospital or poison control center even if no symptoms (such as redness or irritation) develop. IMMEDIATELY transport the victim to a hospital for treatment after washing the affected areas.

INHALATION: IMMEDIATELY leave the contaminated area; take deep breaths of fresh air. If symptoms (such as wheezing, coughing, shortness of breath, or burning in the mouth, throat, or chest) develop, call a physician and be prepared to transport the victim to a hospital. Provide proper respiratory protection to rescuers entering an unknown atmosphere. Whenever possible, Self-Contained Breathing Apparatus (SCBA) should be used; if not available, use a level of protection greater than or equal to that advised under Protective Clothing.

INGESTION: DO NOT INDUCE VOMITING. Corrosive chemicals will destroy the membranes of the mouth, throat, and esophagus and, in addition, have a high risk of being aspirated into the victim's lungs during vomiting which increases the medical problems. If the victim is conscious and not convulsing, give 1 or 2 glasses of water to dilute the chemical and IMMEDIATELY call a hospital or poison control center. IMMEDIATELY transport the victim to a hospital. If the victim is convulsing or unconscious, do not give anything by mouth, ensure that the victim's airway is open and lay the victim on his/her side with the head lower than the body. DO NOT INDUCE VOMITING. Transport the victim IMMEDIATELY to a hospital. (NTP, 1992)

Physical Properties

The

Physical Property fields

include properties such as vapor pressure and

boiling point, as well as explosive limits and

toxic exposure thresholds

The information in CAMEO Chemicals comes from a variety of

data sources.

Note: For Vapor Density and Specific Gravity, comparing the value to 1.0 can tell you if the chemical will likely sink/rise in air or sink/float in fresh water (respectively). Short phrases have been added to those values below as an aid. However, make sure to also consider the circumstances of a release. The Vapor Density comparisons are only valid when the gas escaping is at the same temperature as the surrounding air itself. If the chemical is escaping from a container where it was pressurized or refrigerated, it may first escape and behave as a heavy gas and sink in the air (even if it has a Vapor Density value less than 1). Also, the Specific Gravity comparisons are for fresh water (density 1.0 g/mL). If your spill is in salt water (density about 1.027 g/mL), you need to adjust the point of comparison. There are some chemicals that will sink in fresh water and float in salt water.

Note: For Vapor Density and Specific Gravity, comparing the value to 1.0 can tell you if the chemical will likely sink/rise in air or sink/float in fresh water (respectively). Short phrases have been added to those values below as an aid. However, make sure to also consider the circumstances of a release. The Vapor Density comparisons are only valid when the gas escaping is at the same temperature as the surrounding air itself. If the chemical is escaping from a container where it was pressurized or refrigerated, it may first escape and behave as a heavy gas and sink in the air (even if it has a Vapor Density value less than 1). Also, the Specific Gravity comparisons are for fresh water (density 1.0 g/mL). If your spill is in salt water (density about 1.027 g/mL), you need to adjust the point of comparison. There are some chemicals that will sink in fresh water and float in salt water.

| Chemical Formula: |

|

Flash Point:

279°F

(NTP, 1992)

Lower Explosive Limit (LEL):

1.6 %

(calculated)

(NTP, 1992)

Upper Explosive Limit (UEL):

9.8 %

(estimated)

(NTP, 1992)

Autoignition Temperature:

1224°F

(USCG, 1999)

Melting Point:

82°F

(NTP, 1992)

Vapor Pressure:

5 mmHg

at 280°F

; <0.01 mmHg at 68°F

(NTP, 1992)

Vapor Density (Relative to Air):

3.65

(NTP, 1992)

- Heavier than air; will sink

Specific Gravity:

1.095

at 82.4°F

(USCG, 1999)

- Denser than water; will sink

Boiling Point:

516.4°F

at 760 mmHg

(Decomposes)

(NTP, 1992)

Molecular Weight:

105.14

(NTP, 1992)

Water Solubility:

greater than or equal to 100 mg/mL

at 57°F

(NTP, 1992)

Ionization Energy/Potential: data unavailable

IDLH: data unavailable

AEGLs (Acute Exposure Guideline Levels)

No AEGL information available.ERPGs (Emergency Response Planning Guidelines)

No ERPG information available.PACs (Protective Action Criteria)

| Chemical | PAC-1 | PAC-2 | PAC-3 | |

|---|---|---|---|---|

| Diethanolamine (111-42-2) | 3 mg/m3 | 22 mg/m3 | 130 mg/m3 | LEL = 16000 ppm |

(DOE, 2024)

Regulatory Information

The

Regulatory Information fields

include information from

the U.S. Environmental Protection Agency's Title III Consolidated List of

Lists,

the U.S. Cybersecurity and Infrastructure Security Agency's Chemical Facility

Anti-Terrorism Standards,

and the U.S. Occupational Safety and Health Administration's

Process Safety Management of Highly Hazardous Chemicals Standard List

(see more about these

data sources).

EPA Consolidated List of Lists

| Regulatory Name | CAS Number/ 313 Category Code |

EPCRA 302 EHS TPQ |

EPCRA 304 EHS RQ |

CERCLA RQ | EPCRA 313 TRI |

RCRA Code |

CAA 112(r) RMP TQ |

|---|---|---|---|---|---|---|---|

| Diethanolamine | 111-42-2 | 100 pounds | 313 |

(EPA List of Lists, 2024)

CISA Chemical Facility Anti-Terrorism Standards (CFATS)

No regulatory information available.OSHA Process Safety Management (PSM) Standard List

No regulatory information available.Alternate Chemical Names

This section provides a listing of alternate names for this chemical,

including trade names and synonyms.

- BIS(2-HYDROXYETHYL)AMINE

- BIS(HYDROXYETHYL)AMINE

- BIS-(2-HYDROXY)ETHYLAMINE

- BIS-2-HYDROXYETHYLAMINE

- DI(2-HYDROXYETHYL) AMINE

- DI(BETA-HYDROXYETHYL)AMINE

- DIETHANOLAMINE

- DIETHYLOLAMINE

- 2,2'-DIHYDROXYDIETHYAMINE

- 2,2'-DIHYDROXYDIETHYL AMINE

- 2,2'-DIHYDROXYDIETHYLAMINE

- DIOLAMINE

- ETHANOL, 2,2'-IMINODI-

- 2-[(2-HYDROXYETHYL)AMINO]ETHANOL

- 2,2'-IMINOBISETHANOL

- 2,2'-IMINOBIS[ETHANOL]

- 2,2'-IMINODI-1-ETHANOL

- IMINODIETHANOL

- 2,2'-IMINODIETHANOL

- N,N'-IMINODIETHANOL

- N,N-BIS(2-HYDROXYETHYL)AMINE

- N,N-DIETHANOLAMINE

- NCI-C55174